Hydronic balancing is crucial for heating, ventilation, and air conditioning (HVAC) systems to run efficiently as it ensures an efficient and even distribution of water to all parts of the system. Proper balancing optimises performance, reduces energy consumption, and ensures occupant comfort. Here we explore what hydronic balancing is, how it works, the role of advanced valves, and the consequences of an unbalanced system.

What is Hydronic Balancing?

Hydronic balancing is the process of adjusting the water flow within an HVAC system to ensure each terminal unit, such as radiators or fan coil units, receives the designed flow rate. Without balancing, water may flow unevenly, causing some areas to overheat or remain cold.

An unbalanced system often results from high resistance in certain parts of the network, forcing water to take paths of least resistance. Balancing addresses these inefficiencies, enabling the system to deliver the required comfort while minimising energy wastage.

How Does Hydronic Balancing Work?

Hydronic balancing typically involves measuring and adjusting water flow rates across the HVAC network. The process starts with identifying system design parameters, such as flow rates and pressure drop for each component. Specialised balancing valves are installed to regulate flow in various parts of the system.

Key Steps in Hydronic Balancing:

- Preliminary Inspection: Verify the system design, layout, and operating conditions.

- Flow Measurement: Use flow meters or sensors to measure the actual flow rates at various points.

- Valve Adjustment: Adjust balancing valves to achieve the desired flow distribution.

- Verification: Re-measure flow rates to confirm the system is balanced.

Balancing can be either static or dynamic. Static balancing uses manual valves to set a fixed flow rate, while dynamic balancing employs advanced valves that automatically adjust to changes in system conditions.

Pressure Independent Control and Balancing Valves

Pressure independent control valves (PICVs) represent a modern solution for achieving hydronic balance in dynamic HVAC systems. These valves combine the functions of flow regulation and pressure control, ensuring stable operation under varying loads.

Features of PICVs:

- Automatic Flow Regulation: PICVs maintain a constant flow rate despite pressure fluctuations.

- Integrated Control: They often include modulating control capabilities to optimise energy usage.

- Reduced Commissioning Effort: The automatic nature of PICVs simplifies the balancing process, saving time during system commissioning.

PICVs are particularly effective in systems with varying demand, such as multi-zone buildings or systems with frequent load changes.

Balancing Valves

Traditional balancing valves, both static and dynamic, play a critical role in distributing flow:

- Static Balancing Valves: Designed to manually set flow rates, they are ideal for systems with stable demand. However, they require precise measurement and adjustment during commissioning.

- Dynamic Balancing Valves: These valves adjust automatically to maintain consistent flow rates, even when pressures vary. They are suitable for systems with frequent demand changes.

Examples of Danfoss Valves

Danfoss, a leader in HVAC technology, offers a wide range of valves designed to facilitate hydronic balancing. Here are a few examples:

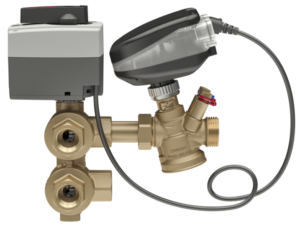

- Danfoss AB-QM Valve: This pressure-independent balancing and control valve ensures precise flow regulation and modulates according to the building’s demand. Its design simplifies installation and commissioning.

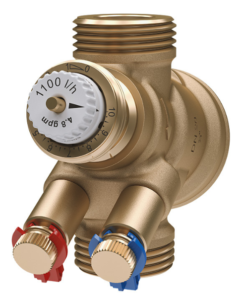

- Danfoss ASV Valve: This is a dynamic balancing valve that automatically maintains a preset flow rate. It is particularly effective in balancing risers in multi-story buildings.

- Danfoss MTCV Valve: This thermostatic control valve balances domestic hot water systems, ensuring consistent water temperature and preventing energy losses.

These products illustrate the versatility and innovation Danfoss brings to hydronic balancing.

Consequences of Unbalanced HVAC Systems

An unbalanced HVAC system leads to several issues, both for building occupants and system operators. Below are the major consequences:

Inefficient Energy Use

When the water flow is uneven, pumps and boilers must work harder to meet demand. This increases energy consumption and operating costs.

Inconsistent Comfort Levels

Uneven water distribution results in some areas being too hot or too cold, leading to discomfort for occupants.

Increased Wear and Tear

Pumps, valves, and other components experience additional stress in unbalanced systems. Over time, this reduces their lifespan and increases maintenance costs.

Higher Operational Costs

Unbalanced systems often require frequent adjustments and repairs, raising operational expenses.

Potential System Failure

Prolonged imbalance can cause severe issues, such as overheating of boilers or freezing of pipes, leading to costly system breakdowns.

Importance of Hydronic Balancing

Achieving hydronic balance is not merely a best practice but a necessity for modern HVAC systems. It ensures efficient energy usage, minimises wear on components, and creates a comfortable indoor environment. Balancing is particularly crucial in buildings aiming for sustainability certifications like LEED or BREEAM, as it directly impacts energy performance.

Hydronic balancing is a cornerstone of efficient HVAC operation. By ensuring even water distribution and leveraging advanced valves like those from Danfoss, building managers can optimise energy use, improve occupant comfort, and extend the lifespan of their systems. The adoption of pressure-independent control valves further simplifies the process, making hydronic balancing accessible and effective in dynamic environments.

Ignoring the need for balancing leads to inefficiencies and higher costs, making it an essential aspect of HVAC design and maintenance. For anyone managing an HVAC system, investing in hydronic balancing is a decision that pays dividends in performance, sustainability, and long-term savings.

Automated Control Solutions (ACS) is an importer and distributor of Building Management Systems, Energy Efficient Building Automation Controllers, sensing and control equipment used to control heating, ventilation and air-conditioning (HVAC) systems and field devices such as PICVs..

We understand that our customers want the latest technologies, which is why we have partnered with innovative, dynamic companies like Danfoss to ensure that we offer our customers a complete basket of products to cover any Automated Control Solutions.